What makes an automated picking system truly high-performance? It’s not just speed — it’s the ability to deliver ROI across layout, runtime, and flexibility. This guide explores how to get there.

When building the business case for automated warehouse picking, two main factors typically drive the ROI:

1. How many hours per day can your system operate? With full automation — no human operators — the answer is often 20+ hours per day, including nights and weekends.

2. How much throughput can you achieve per hour? A high-speed robot like the HKM1800 maximizes picks per minute, every minute.

Multiply these two — extended runtime and high throughput — and your automation investment pays off quickly. But that’s only the foundation — factors like cell design, article presentation, and flow all influence the real return.

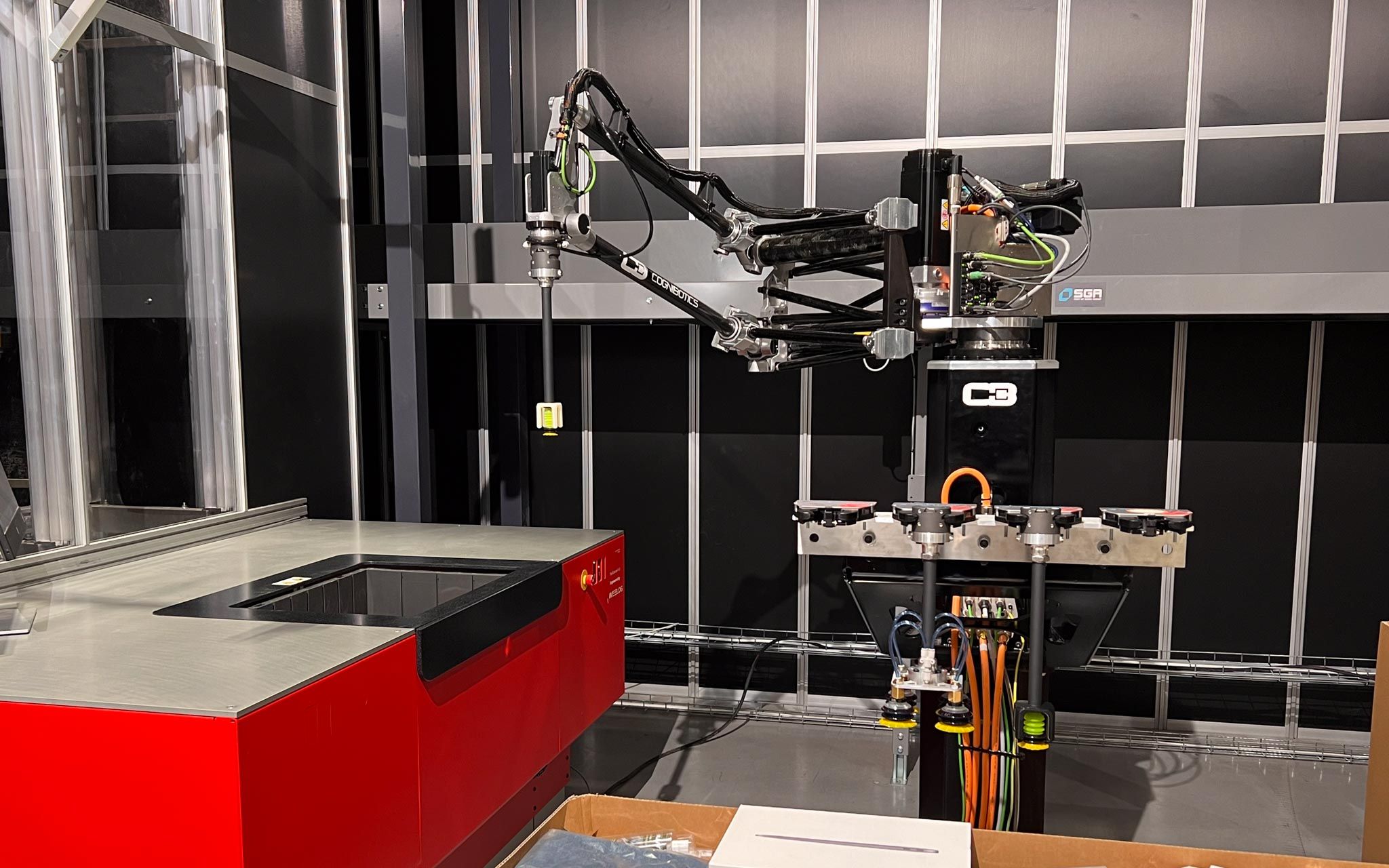

Traditional warehouse layouts are shaped by human constraints. But with automated picking robots, like the HKM1800, you can rethink everything — from space to speed to cost per pick.

The HKM1800 combines long reach, lightweight mechanics, and ultra-fast cycle times, unlocking cell designs that boost layout flexibility and productivity.

So what does a future-proof picking cell actually look like in practice — and how do you design one that delivers, shift after shift? Let’s break it down.

A modern automatic picking system typically includes a robot, compact storage, and an automated carton erector. It’s a strong foundation for 24/7 operations — no manual intervention required.

But despite full automation, many systems still hover around 300 picks per hour — a limit originally set by what a human picker could do. The real constraints today are more technical:

How quickly new articles are presented to the robot

How many destination options (e.g. cartons or order locations) the robot can place into

These two factors — article inflow and placement flexibility — are what truly limit throughput in many automated warehouse picking systems.

What helps? Target: Double the active presentations and placements, and you can realistically double your pick speed — potentially halving your cost per pick in the process.

Increasing the number of available customer cartons (e.g. from 2 to 4) gives the robot more opportunities to batch pick efficiently and avoid idle time.

Now we introduce one additional article presentation — and expand the total number of picking destinations to four totes.

For a high-speed robot like the HKM1800, this setup immediately increases the active pick pool. With 1,200–2,000 picks per hour, the robot keeps up without hesitation.

By enabling four customer totes for placement, the WMS system can batch orders close together, when they ask for similar articles. This creates a more efficient flow where:

More picks come from the same article presentation

Less switching = Less strain and higher throughput in your compact storage

Impact on infrastructure: This setup helps you to buy a smaller compact storage or postpone expansion, or scale output without increasing the compact storage performance.

Bonus: With smart tote compacting, HKM1800 can consolidate half-filled totes of the same SKU in its spare time — freeing up storage space and improving fill rate in the compact warehouse.

Modern logistics flows aren’t static — they shift over time, with product mix, volume spikes, and operational edge cases. This is where Autonomous Mobile Robots (AMRs) offer real value: they make the picking cell part of a larger, flexible system.

With AMRs feeding or receiving from the HKM1800, you can support flows like:

Manual add-ons: Route a tote to a manual station to insert

Explosive items from controlled zones

Fragile or tangled goods (e.g. springs, wires)

Loose-weight picks like 50 screws or washers

Live consolidation: AMRs can transport partially filled totes for

Merging similar SKUs

Freeing up totes for restocking

Reducing unnecessary compact storage usage

Leverage low-load periods

Use robot spare time to add values beyond picking. For example return handling, seasonal reflow, or layout shifts

Why it matters:Adaptability. If you manage warehouse operations, you know it's rarely one-size-fits-all — especially when demand changes week to week. AMRs give you the flexibility to adapt without redesigning the entire system.

When your robot has both the speed and workspace, like the HKM1800, you can do more with every square meter — also during off-peak hours.

Use available capacity in your automated warehouse picking system to introduce new value-adding flows:

Add a poly/paperbagging machine to win customers also having low-cost items by offering cost effective packaging

Include a decanting station to convert inbound cartons into tote-based picking flows

Already seeing ROI from automated picking? Every new process you add builds on that — improving asset utilization and strengthening the business case without major reinvestment.

The HKM1800 isn’t just a fast robot — it’s a high-speed, lightweight productivity tool designed to power the next generation of automated warehouse picking systems.

Maximize picks per hour

Extend operational hours across shifts and weekends

Optimize layout and reduce infrastructure pressure

Handle layout changes, AMRs, and flow variants with ease

Design for uptime. Plan for change. That’s how automation delivers ROI — today and tomorrow.