What would you think if you saw a pick-and-place robot that sorts complex goods such as fruits, vegetables, or flexible objects into boxes four times faster than a human? Impossible? Not anymore.

The new sensation for order-picking tasks is showcased at Automatica. Cognibotics and KEBA present the new ultra-high-performance robot with a large range and high throughput: HKM1800.

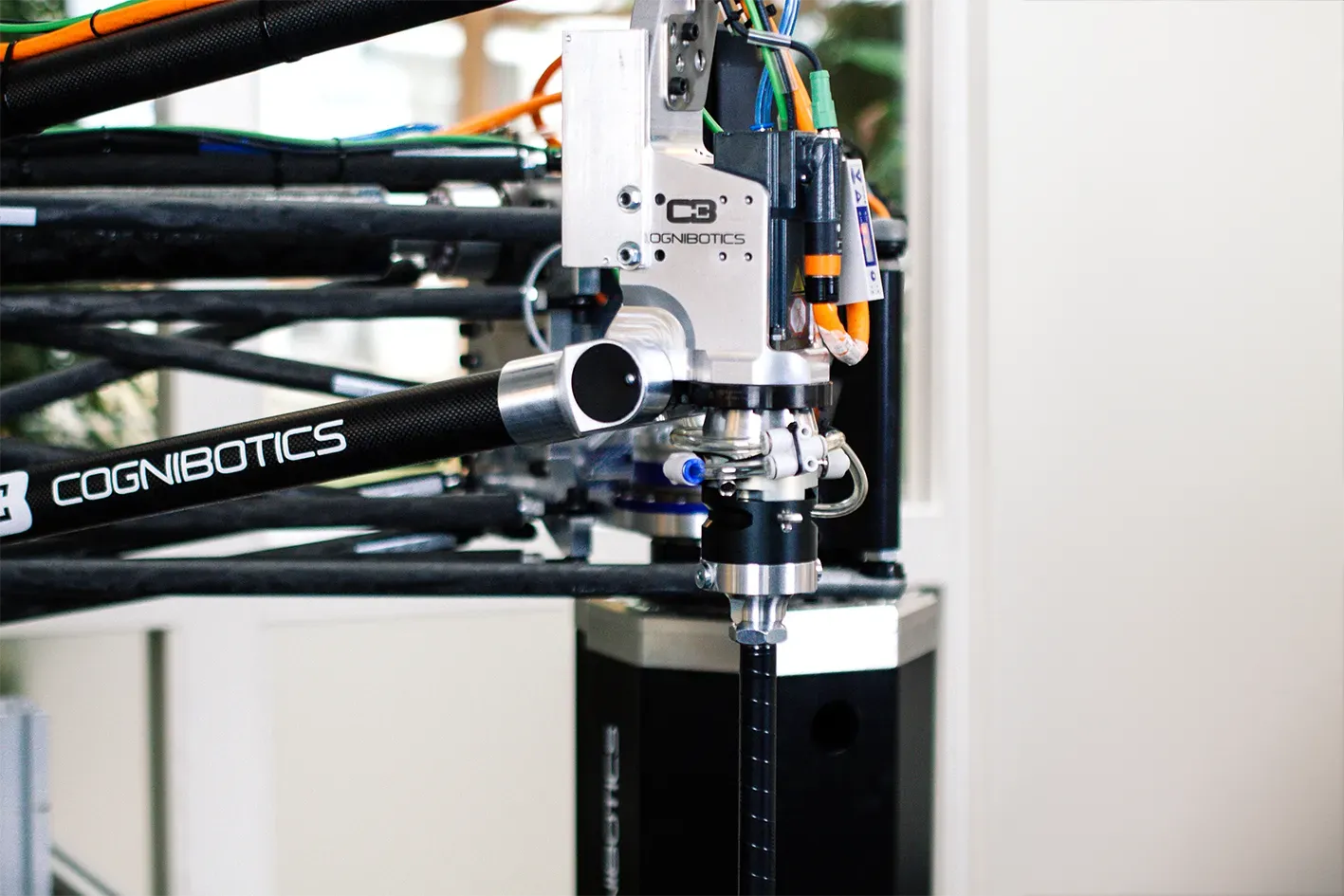

At Automatica 2023 (booth B5, Stand 504), you will witness a world premiere: Cognibotics introduces the HKM1800 for the first time. This high-performance robot opens up new possibilities for robot-assisted material handling, especially in environments like warehouses and distribution centers in intralogistics, where multiple pick-and-place positions cover a large workspace. Compared to conventional SCARA, Delta, and 6-axis robots, it is optimized for pick-and-place applications with superior performance and precisely designed degrees of freedom. It is made of lightweight high-performance material and configured to move extremely low mass, enabling peak performance with minimal energy consumption. Since 80% of the manipulator’s weight is in its stationary base, the energy consumption is very low, while the achievable performance is significantly higher than previous solutions.

While a person can maintain a pace of 300-500 pick-and-place cycles per hour, the HKM1800 performs over 2000 cycles per hour with the option of reaching much further than what is reasonable for a human. The moving mass of the robot is less than 125 kg, but it can handle a maximum payload of 7.5 kg and has a reach of 1800 mm, covering an impressive workspace of 10 square meters on the floor. Mats Jonsson, Business Unit Manager at Cognibotics AB, says, “The hybrid kinematics manipulator combines the advantages of serial and parallel kinematics, allowing for minimal moving masses and the shortest possible cycle times over large workspaces.

HKM1800 performs over 2000 cycles per hour with the option of reaching much further than what is reasonable for a human

The HKM 1800 is equipped with the KEBA system. Michael Garstenauer, Product Manager Robotics at KEBA Industrial Automation, states, “We are proud to be part of the HKM. This project demonstrates how our customers can implement their core technology and bring it to the market quickly and reliably based on our mature and powerful robotics platform, KeMotion.” KEBA provides the foundation for Cognibotics’ unique performance, including servo drives, robot-specific safety technology, motion planners, program interpreters, mobile operator solutions, and interfaces for system integration. The integration capabilities of the KEBA system enable seamless collaboration and offer innovation and investment protection for Cognibotics. Garstenauer adds, “With KEBA, Cognibotics has a stable and long-term partner who can provide customers with security regarding service and availability of spare parts for the automation system. Robotics is evolving towards application-optimized solutions, and we look forward to many more projects like this!”

SICS.AI, a leader in artificial intelligence, provides HKM1800 with its groundbreaking digital ‘robot brain.’ This advanced solution rapidly adapts to new inventory items in real-time. Its optional damaged goods identification ensures 24/7 operations with exceptional accuracy. Seamlessly integrating into any environment, the robot brain handles diverse data sources, equipment, and metadata. SICS vision technology enhances the robot’s efficiency, productivity, and versatility, opening up possibilities for a wide range of applications in material handling and logistics.

Commenting on the collaboration with Cognibotics, The Founder of SICS.AI, Karim Nouira, mentions, “We work towards a disrupt in automation through next generation AI, redefining the boundaries of what robots can achieve, enabling automation systems to learn, adapt, and improve continuously, meeting the needs of production flexibility and efficiency. It is a pleasure to unite the power with a company sharing the same vision.”

HKM1800 is equipped with an efficient tool changing system, providing seamless integration and enhanced operational capabilities. This tool changing system enables the robot to swiftly switch between different tools, facilitating the handling of diverse materials and products with precision and efficiency. The seamless integration of the tool changing system with the HKM1800 allows for uninterrupted workflow, eliminating the need for manual intervention or time-consuming reconfiguration. With the ability to quickly adapt to varying tasks and requirements, the HKM1800 maximizes productivity and versatility, enabling businesses to optimize their material handling processes. This not only streamlines operations but also improves overall performance, making the HKM1800 a valuable asset for industries seeking seamless and efficient material handling solutions.

Press contact

Cognibotics

CEO

Fredrik Malmgren

fredrik.malmgren@cognibotics.com

+46 73 419 62 96