Nowaste Logistics from Helsingborg has become the first in the world to install a material-handling robot that can revolutionize the industry. Cognibotics HKM 1800, complemented with advanced AI from SICS, is set to deliver a new level of productivity and simplicity. The solution has been developed with the support of Vinnova and has attracted significant attention at the Automatica Fair 2023, where it showcased performance at an entirely new level.

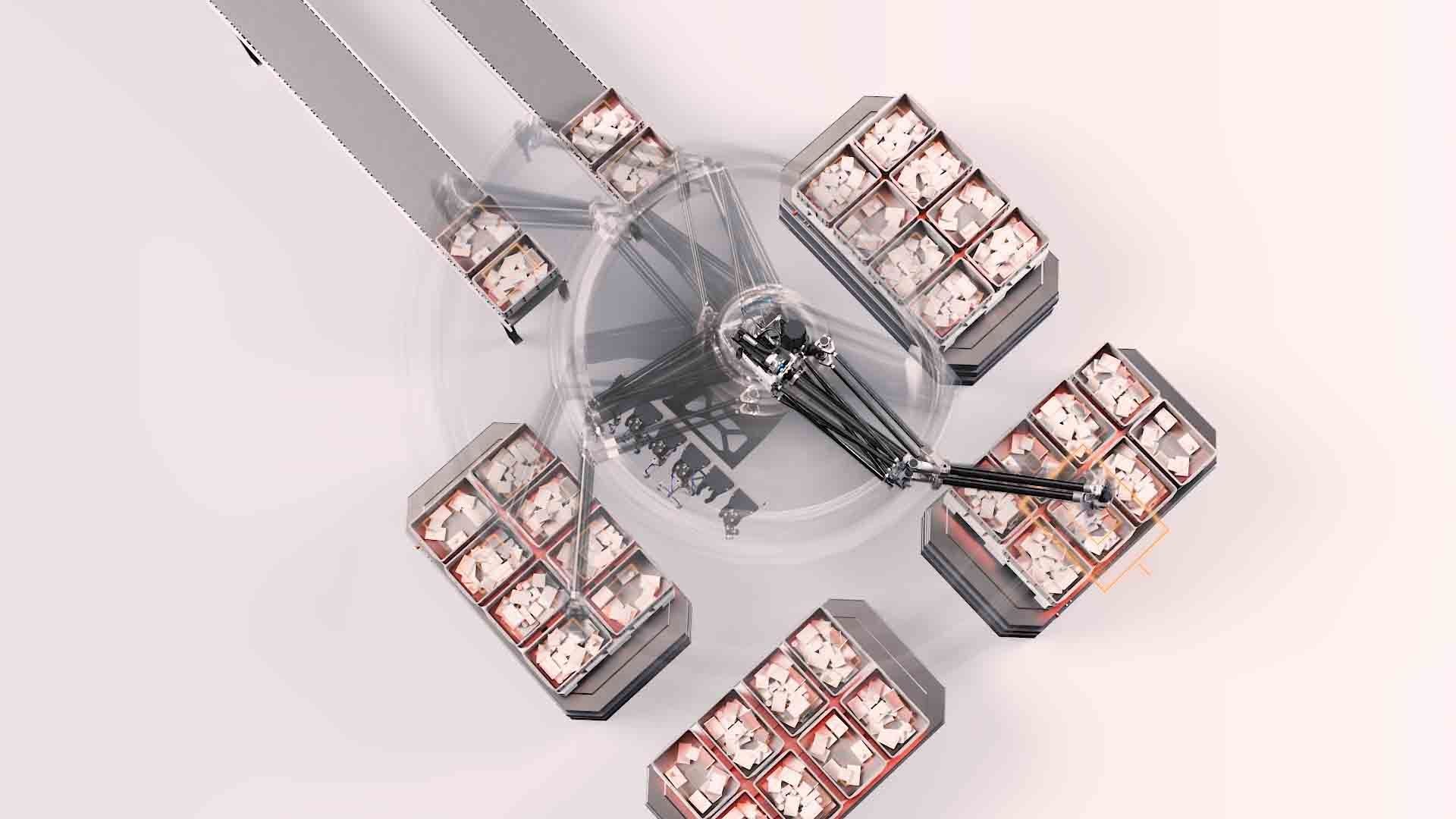

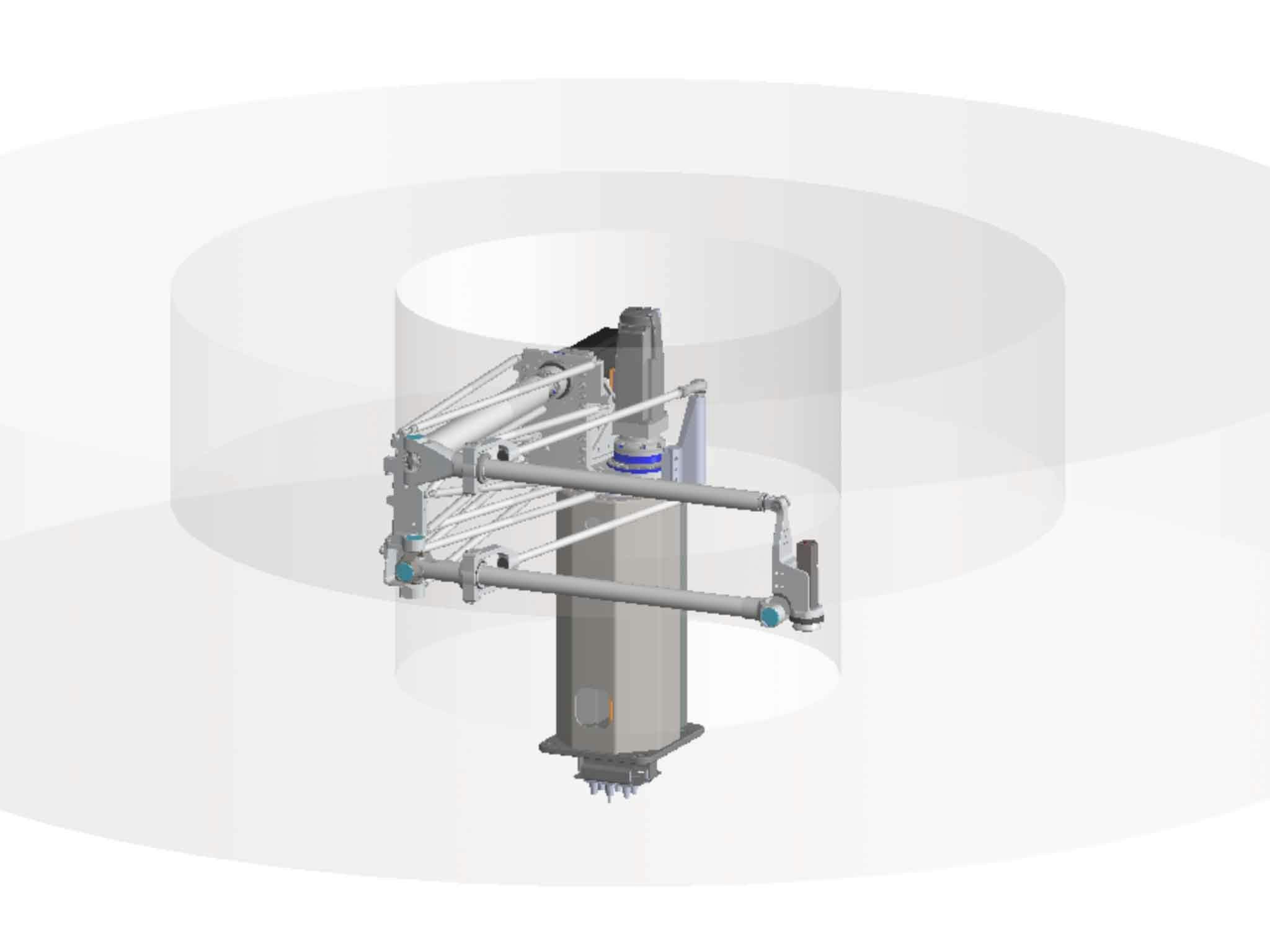

Mats Jonsson, business area manager for HKM1800, says that with HKM's reach of 1.8 meters and speed of around 2000 picks per hour, we can create a whole new productivity in intralogistic picking. The robot's work area, which is a whole 10 square meters, can be the biggest customer benefit as it enables completely new and much better automation layouts in the warehouse.

For example, surrounding equipment and material presentations can be built more simply but also more equipment can be reached for a greater degree of completion, i.e., customer benefit. The system is further equipped with a quick tool change, which gives the customer the ability to handle a large range of goods with varying weights, shapes, and sizes.

Furthermore, the collaboration with SICS AI and their innovative self-learning AI is extremely exciting as we have already been able to match the robot's high performance but also see how much easier it has become for the customer to handle a large amount of varied goods thanks to a smarter and faster AI.

Order picking is a known difficult-to-plan bottleneck in warehouse management since current pick and place robots often encounter limitations, especially in the unstructured environment of e-commerce warehouses, with rapid changes and wide product assortment.

Mats Jonsson, business area manager for HKM1800, says that with HKM's reach of 1.8 meters and speed of around 2000 picks per hour, we can create a whole new productivity in intralogistic picking. The robot's work area, which is a whole 10 square meters, can be the biggest customer benefit as it enables completely new and much better automation layouts in the warehouse.

paragraphXL

paragraphXL

paragraphXL

paragraphLarge

paragraphLarge

paragraphLarge

paragraphSmall

paragraphSmall

paragraphSmall

Business Development Manager

FeatureItemDescription

FeatureItemDescription

FeatureItemDescription

FeatureItemDescription

{

"_uid": "6ef0522e-8861-4450-9e7c-a9a59a142857",

"component": "codeExampleBlok",

"codeExample": "using Main.EstunMotion\n\nfunction main()\n init_ER20()\n\n # create targets for iso-cube\n var ti = JointTarget(0.0, 22.7, 46.5, 0.0, -80.0, 90.0)\n var t2 = JointTarget(28.3, -3.0, 61.5, 33.5, -59.2, 71.3)\n var t3 = JointTarget(-28.3, -3.8, 61.5, -33.5, -59.2, 108.6)\n var t4 = JointTarget(-14.5, 66.9, 7.7, -15.9, -75.1, 93.9)\n var t5 = JointTarget(14.5, 66.9, 7.7, 15.0, -75.1, 86.0)\n \n var i = 0\n while i < 2\n movJ (er20, t1)\n movJ (er20, t2)\n movJ (er20, t3)\n movJ (er20, t4)\n movJ (er20, t5)\n i += 1\n end\n\n return 0\nend",

"codeLanguage": "juliet",

"codeSoftWrap": false,

"codeHeaderText": "",

"copyButtonText": "Copy",

"codeLineNumbers": true,

"copiedButtonText": "Copied"

}