Precision, speed, and efficiency are critical factors to success In the world of industrial automation. Maximizing robot performance without compromising quality, and without costly mechanical iterations, is fundamental for efficiency and rentability, especially in high-value processes like cutting, welding, or large-scale 3D printing.

Cognibotics is leading the way with CAPE, Cognibotics Algorithmic Performance Enhancing software. CAPE allows robots to achieve high-precision, high-speed motion across the entire work envelope, without compromising robustness or requiring motion specific tuning.

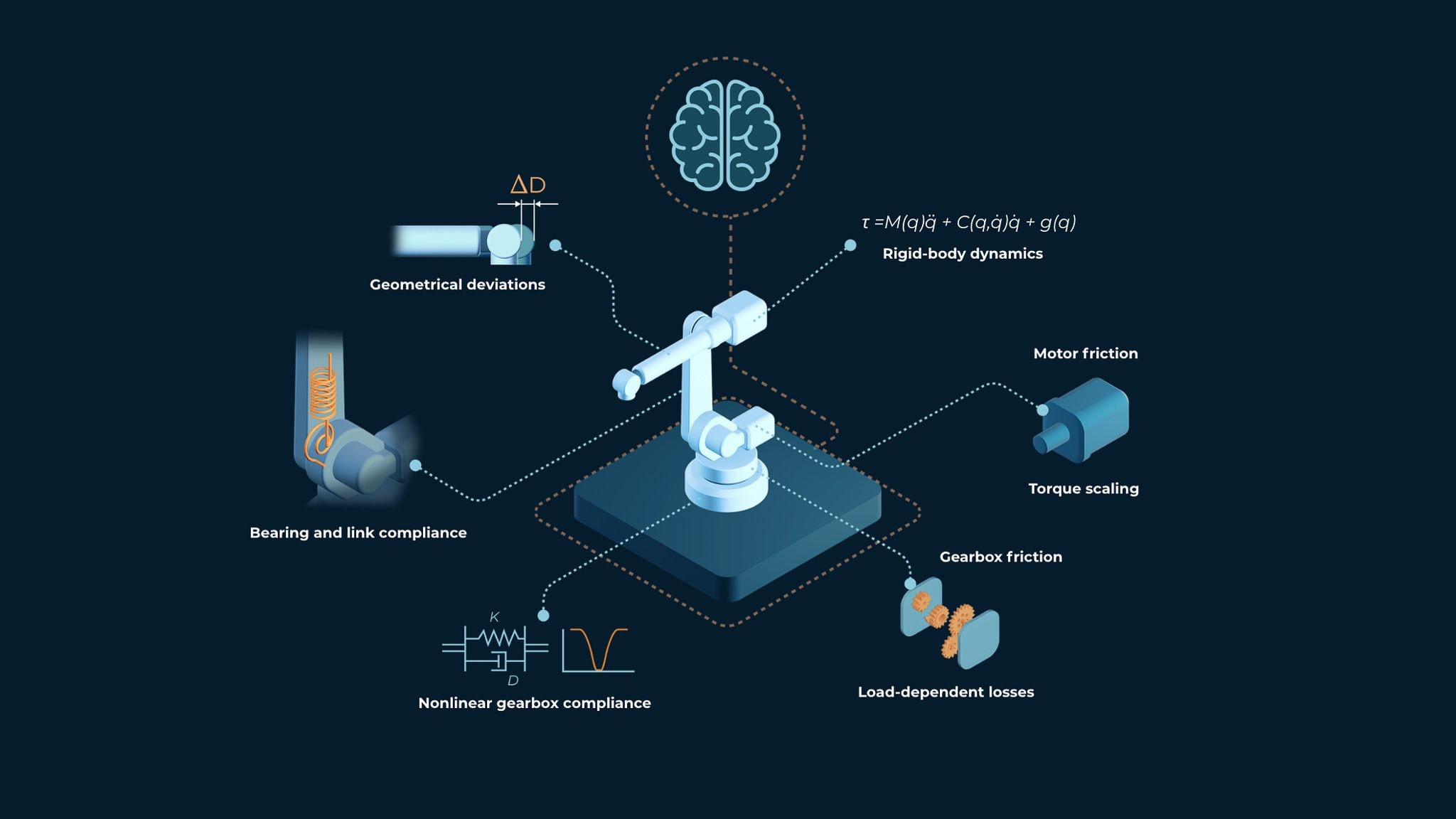

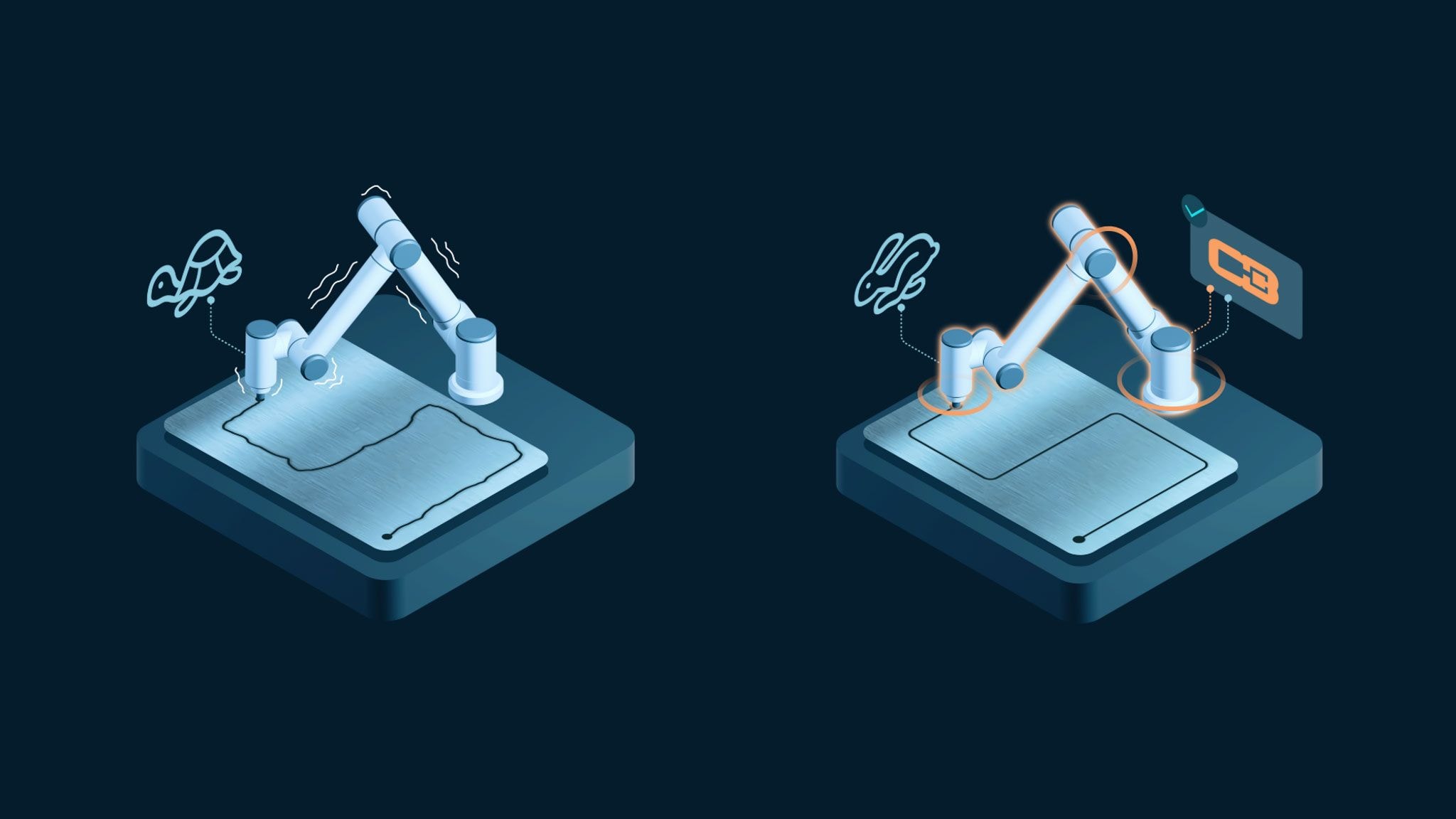

Robots operating in high-speed, high-accuracy environments face challenges like motion-induced vibrations, loss of precision under load, and unpredictable performance across the workspace. These issues originate from several complex and interacting physical effects such as joint and link elasticity, resonance propagation and dynamics of the robot structure, and transmission losses.

Accurate identification of all these effects is rarely addressed but critical for top performance. Cognibotics' CAPE solves this by integrating advanced tools for system identification and by using a detailed elasto-dynamic model of the robot structure to shape motion trajectories. This enables the robot to:

Avoid exciting resonances and cross-resonances

Use available torque efficiently, allowing higher speeds and lower power consumption

Maintain high motion fidelity across a wide range of tasks and payloads

Unlike conventional approaches, the CAPE-model remains valid across the entire workspace, delivering consistent, optimized performance without manual tuning.

CAPE unlocks performance that is often left unused by default robot control systems. By tapping into a deeper understanding of robot mechanics and process dynamics, Cognibotics enables:

More productive use of existing robots

Greater performance from cost-effective hardware

Reduced energy consumption through more efficient torque use

Scalable deployment without fragile, case-specific tuning

CAPE is especially powerful for automation providers looking to standardize high-end motion performance across product lines or customer installations.

Improved motion quality actively drives robotics automation in areas where this was previously difficult to justify. This creates unique cost advantages in high-value manufacturing and new business opportunities for automation providers.

Examples applications include:

Laser Cutting: Smooth, rapid movements reduce edge defects and minimize time per part.

Plasma Welding: Better path tracking improves weld quality and lowers rework.

Large-Scale 3D Printing: Accurate deposition with high-speed movements, avoiding ripples and path distortion.

Injection Molding: Fast part extraction without cycle-time penalties or impact on positioning.

CAPE enables industrial robots to run faster and more precisely by avoiding resonance and intelligently maximizing torque use, without requiring high-end mechanical structures or endless filter tuning. The result is shorter cycle times, higher process quality, and automation systems that scale reliably.

For deeper insights, these articles show how Juliet &

Robot Motion Quality: The Missing Link in Scalable, Cost-Effective Automation (link): why motion quality is a decisive factor for throughput, process stability, and lifecycle cost in advanced automation systems.

CAPE: Boosting Robot Speed and Accuracy with Model-Based Motion Control (link): explores Cognibotics’ model-based motion control software, which increases robot speed and accuracy across the full workspace, enabling higher productivity and consistent process quality without mechanical redesign or extensive manual tuning.

Accurate Robots: The Foundation for Scalable, Flexible Automation (link): describes how mastering elasto-kinematics and robot calibration creates predictable, high-quality robot motion, enabling reliable digital twins, effective AI and vision integration, and scalable deployment of flexible automation across cells, product variants, and production volumes.

To learn how CAPE can bring high-performance motion to your robots in a predictable, efficient, and scalable manner.